Experience a Lower Total Cost of Ownership with an Electric Steam Generator

SRP Offers a “No-Cost Electrification Consultation”

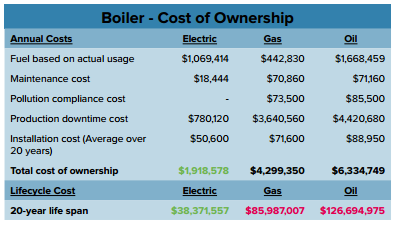

Modern gas fired boilers carry significant hidden costs including forced production down time, extensive maintenance requirements and emission permitting fees.

Chromalox’s low and medium voltage electric steam generators are an economical and versatile alternative to gas and oil fired boilers.

Electric Boilers offer:

- Fossil fuel burners have lowered efficiencies when not running at their designed power (when not burning 100% capability)

- Fossil fuel burners have lowered efficiencies when burners are dirty (i.e. soot build up)

- Measuring true thermal efficiency is difficult with fossil fuel burners (i.e. the boiler thermal conversion, not just the burner)

- Thermal efficiencies of electric is 98% or better!

- No downtime for cleaning of burners and firetubes (Usually at least a 2 week shutdown per year in addition to other cleanings)

- No waste during startup / shutdown (burners change over 4x the air volume before firing every time)

- No waste during idle time (i.e. plant shutdown, or low usage are very in-efficient)

- No certified boiler tech needed to operate the boiler (24×7 in many cases)

- No cost of pollution equipment

- No cost of pollution maintenance

- No cost of pollution supply (such as ammonia for injection or cleaning/disposal of filters)

- No cost or time for air permitting

- No cost of carbon credits

- No cost of maintaining pollution stacks

- No cost of Legal for compliance

- No cost of additional floor space for larger fossil fuel boiler, supply lines and pollution equipment (Electric boilers have a much smaller “foot print”)

Electric steam generators not only support a zero carbon initiative, but also provide the lowest total cost of ownership.

Historically, fuel-fired boilers have been used instead of electric systems due to the perceived lower operating costs. In looking at steam generator efficiencies one needs to consider the thermal conversion and operational efficiency achieved. Maintenance costs are also reviewed in detail as electric steam generation offers such advantages as no burner, blowers, and few moving parts. This drastically reduces maintenance requirements and minimizes production downtime.

In addition to steam generation there are numerous other applications where electric process heating can replace fuel fired heating systems. With the advancement of DirectConnect medium-voltage technology, large electric heating systems can be installed and operated at much lower costs than low-voltage heating systems.

For both the steam generators and process heating systems, utilizing electricity produces zero emissions at the installation site which can help industrial and commercial end users achieve their carbon footprint reduction goals.

To sum it all up, Chromalox’s low and medium voltage electric steam generators are an economical and versatile alternative to gas and oil fired boilers. They address the need for zero emission steam and hot water boiler solutions, provide the lowest total cost of ownership and are designed and manufactured for easy installation and operational efficiency.

Contact Watt Solutions today for more information on electric steam generators and additional electric process heating and temperature maintenance solutions.

Watt Solutions – phone: (602) 373-9663, email: [email protected] (no .com)